Title: Understanding the OSHA Process Safety Management (PSM) Standard – 29 CFR 1910.119 ( Free Download )

Understanding the OSHA Process Safety Management (PSM) Standard – 29 CFR 1910.119

Author: MohammadSadegh Ahmadi

Instructor and Industrial Safety Specialist

Date: April 28, 2025

Abstract

The Process Safety Management (PSM) standard outlined by OSHA under 29 CFR 1910.119 provides a comprehensive framework to prevent catastrophic releases of highly hazardous chemicals. This paper explains the essential components of the PSM standard, emphasizing the importance of proactive hazard identification, employee participation, mechanical integrity, and management of change. By systematically implementing the 14 elements of PSM, organizations can effectively minimize risks, protect personnel, facilities, and the environment, and cultivate a culture of safety excellence in the chemical processing industries.

Keywords

Process Safety Management (PSM); OSHA 29 CFR 1910.119; Hazard Analysis; Mechanical Integrity; Management of Change; Employee Participation; Industrial Safety; Chemical Process Safety; Emergency Response; Incident Investigation.

Table of Contents

- Introduction

- Literature Review

- Purpose of the PSM Standard

- Scope and Applicability

- Exemptions include

- Key Elements of the PSM Standard

- Employee Participation

- Process Safety Information (PSI)

- Process Hazard Analysis (PHA)

- Operating Procedures

- Training

- Contractor Management

- Pre-Startup Safety Review (PSSR)

- Mechanical Integrity

- Hot Work Permits

- Management of Change (MOC)

- Incident Investigation

- Emergency Planning and Response

- Compliance Audits

- Trade Secrets

- Discussion

- Recommendations

- Future Trends

- Final Conclusion

- References

Introduction

The Occupational Safety and Health Administration (OSHA) developed the Process Safety Management (PSM) standard – 29 CFR 1910.119 – to prevent catastrophic releases of toxic, reactive, flammable, or explosive chemicals. This regulation provides a structured framework for managing the hazards associated with processes involving highly hazardous chemicals (HHCs). It mandates employers to proactively identify, evaluate, and control potential chemical hazards through a systematic application of 14 core elements. Effective PSM implementation not only ensures regulatory compliance but also significantly enhances operational safety, protecting workers, property, and surrounding communities from the devastating impacts of chemical accidents.

Literature Review

The Process Safety Management (PSM) standard, as outlined by OSHA under 29 CFR 1910.119, has been a key element in the chemical and petrochemical industries for preventing catastrophic incidents involving hazardous chemicals. The development of this standard was based on previous accidents and failures in the industry, highlighting the need for a structured approach to process safety.

Numerous studies emphasize that the major cause of chemical plant accidents often stems from failures in safety management systems. According to reports by the U.S. Chemical Safety and Hazard Investigation Board (CSB), numerous incidents, including the Bhopal disaster and the Texas City refinery explosion, underline the significance of robust process safety protocols (CSB, 2007). These incidents demonstrated that the lack of proactive safety measures can result in devastating consequences for human life, the environment, and the economy.

Research on PSM implementation highlights its importance in enhancing operational safety. Several studies indicate that effective hazard analysis, employee involvement, and a strong safety culture contribute to the prevention of accidents (Reason, 1997; Johnson, 2004). In contrast, poor implementation of these elements often leads to catastrophic failures. For example, the BP Texas City explosion was attributed to failures in process hazard analysis (PHA) and lack of management oversight (CSB, 2007).

In recent years, the role of digital tools and artificial intelligence in improving process safety management has garnered attention. Studies suggest that advanced technologies, including predictive analytics and real-time monitoring systems, can help improve hazard identification and mitigate risks (Zhang et al., 2020). As industries continue to evolve, the integration of these technologies into traditional safety practices is expected to provide significant improvements in preventing hazardous events.

Purpose of the PSM Standard

The primary purpose of the Process Safety Management (PSM) standard, as outlined by OSHA under 29 CFR 1910.119, is to prevent the release of highly hazardous chemicals that could result in catastrophic consequences, including loss of life, environmental damage, and significant property damage. PSM aims to protect workers, the surrounding community, and the environment by establishing a comprehensive framework for managing process hazards.

The standard emphasizes the importance of proactive hazard identification, risk assessment, and the implementation of engineering controls, administrative controls, and safe work practices. Through the 14 key elements of PSM, organizations are required to systematically evaluate their processes, ensure that safety protocols are in place, and continuously improve safety performance.

Additionally, the standard fosters a culture of safety within the organization, encouraging the active participation of employees at all levels in safety management. This holistic approach helps reduce the likelihood of accidents by addressing not only the technical aspects of safety but also the human and organizational factors that contribute to process safety incidents.

By adopting PSM, companies can not only comply with regulatory requirements but also significantly enhance their operational safety, reduce the potential for costly accidents, and improve their overall risk management practices.

Scope and Applicability

The Scope and Applicability of the Process Safety Management (PSM) standard, as described in OSHA 29 CFR 1910.119, extends to facilities that use or store highly hazardous chemicals (HHCs) in amounts above specified thresholds. The standard applies to a wide range of industrial operations, including chemical manufacturing, petroleum refining, and other industries where hazardous chemicals are present in significant quantities.

PSM requires that employers implement a comprehensive safety management system for any process that involves a hazardous chemical and meets the threshold quantity criteria. This includes both fixed and mobile processes and applies to facilities that engage in the production, handling, or storage of chemicals that are classified as highly hazardous.

The applicability of the PSM standard extends to all employees involved in the processes that handle hazardous chemicals, including operators, engineers, and maintenance personnel. Additionally, contractors who work on or near these processes are also covered by the provisions of the standard. Employers must ensure that these employees are adequately trained, informed about the hazards, and equipped with the necessary tools and procedures to ensure safety.

However, there are certain exemptions to the applicability of the PSM standard. For instance, the regulation does not apply to facilities that handle or store chemicals in quantities below the threshold limits or those that fall into certain categories such as oil and gas exploration activities (with some exceptions). It also does not apply to transportation-related activities, such as the transport of hazardous chemicals by truck, rail, or ship, unless those chemicals are part of a fixed process.

In summary, the Scope and Applicability of the PSM standard are crucial for ensuring that all facilities that handle hazardous chemicals are subject to the necessary safety protocols. It ensures that the regulation is applied to all relevant industries while recognizing certain exceptions to minimize unnecessary burdens on facilities that do not meet the threshold requirements.

Exemptions include:

Certain processes involving highly hazardous chemicals are exempt from the requirements of the PSM standard. These exemptions typically include:

- Retail facilities.

- Oil or gas well drilling or servicing operations.

- Normally unoccupied remote facilities.

- Hydrocarbon fuels used solely for workplace consumption as a fuel

It is important for organizations to carefully assess their operations against these exemptions to determine their specific obligations under the PSM standard.

Key Elements of the PSM Standard

The Process Safety Management (PSM) standard is structured around 14 key elements that collectively aim to manage hazards associated with highly hazardous chemicals and prevent process-related incidents. These elements are designed to work in an integrated manner, ensuring a comprehensive approach to safety throughout the life cycle of a process, from design and construction to operation and maintenance.

Each element addresses a critical component of process safety and requires specific actions from employers and employees. Together, they establish a robust framework that helps organizations identify, evaluate, and control chemical process hazards effectively.

The standard consists of 14 elements that employers must implement:

Employee Participation (Download)

- Employers must develop a written plan and involve employees in the development and implementation of the PSM elements.

- Process Safety Information (PSI) (Download)

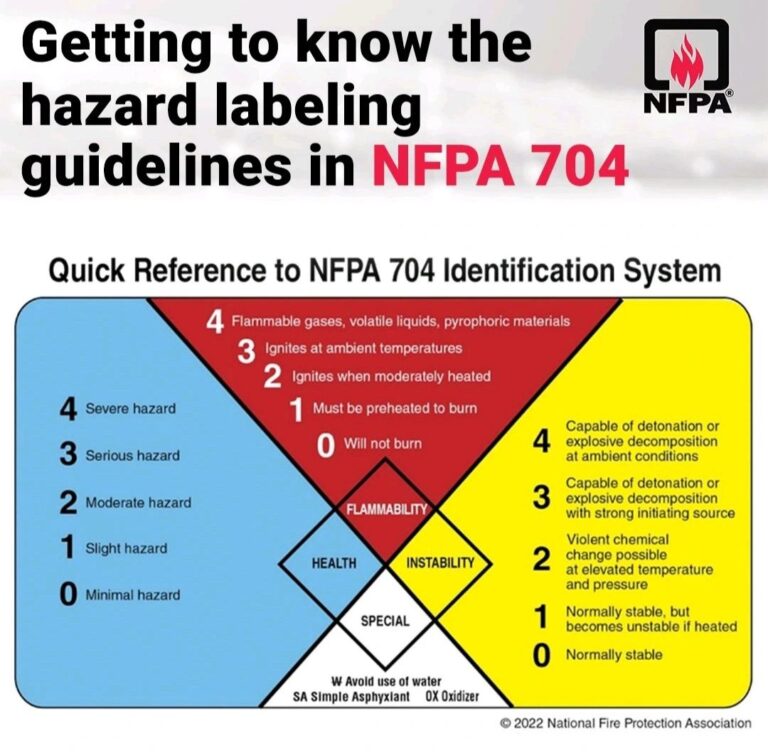

Employers must compile technical information about the chemicals, process technology, and equipment. - Process Hazard Analysis (PHA) (Download)

A thorough evaluation of potential hazards using methods like HAZOP, FMEA, or What-If analysis. Must be updated every 5 years. - Operating Procedures (Download)

Written steps for safe operations, including emergency shutdown and startup procedures. - Training (Download)

Employees must be trained initially and retrained at least every 3 years on the processes they operate. - Contractors (Download)

Employers must ensure contractors are properly trained and informed about hazards. - Pre-startup Safety Review (PSSR) (Download)

A safety review required before introducing HHCs into a new or modified process. - Mechanical Integrity (Download)

Maintenance of critical equipment (e.g., pressure vessels, piping systems) must be ensured through regular inspections. - Hot Work Permit (Download)

Specific procedures and permits must be in place for hot work operations conducted on or near covered processes. - Management of Change (MOC) (Download)

Procedures for evaluating and authorizing changes to processes, equipment, or materials. - Incident Investigation (Download)

All incidents that result in, or could have resulted in, catastrophic releases must be investigated within 48 hours. - Emergency Planning and Response (Download)

A detailed plan for handling emergencies must be in place and coordinated with local emergency responders. - Compliance Audits (Download)

Audits must be conducted at least every 3 years to verify compliance with the standard. - Trade Secrets (Download)

Employers must make necessary information available for PSM even if it involves trade secrets.

Discussion

While the OSHA Process Safety Management (PSM) standard provides a robust framework for managing risks associated with hazardous chemicals, practical implementation in real-world environments poses several significant challenges. Maintaining updated Process Hazard Analyses (PHAs) and Management of Change (MOC) documentation often becomes a burden for organizations, especially as processes evolve and facilities age. Outdated or incomplete hazard analyses leave critical gaps that can lead to serious incidents.

Another common challenge is contractor management. Ensuring that third-party contractors fully understand and adhere to internal safety protocols requires continuous oversight and communication, which, if neglected, can undermine the integrity of the entire safety system. Integrating PSM with other safety and environmental management systems also demands strategic coordination. When siloed, safety efforts can become inefficient or contradictory, increasing overall risk.

Beyond compliance, the effectiveness of PSM depends heavily on the strength of the organization’s safety culture. Without visible leadership commitment, employee engagement, and consistent reinforcement of safety principles, even the best-designed PSM programs can fail. Leading indicators, such as tracking near misses and unsafe behaviors, are often underutilized, causing companies to miss critical early warning signs.

Thus, successful PSM implementation requires more than just meeting regulatory checkboxes; it demands an ongoing, proactive, and deeply embedded risk management philosophy across all organizational levels.

Recommendations

To enhance the effectiveness of Process Safety Management (PSM) programs and ensure sustainable compliance with OSHA’s 29 CFR 1910.119 standard, organizations should consider the following best practices:

- Strengthen Safety Culture:

Foster a culture where safety is a shared value at all levels, from leadership to front-line employees. Leadership commitment must be visible and continuous to drive engagement and accountability. - Implement Leading Indicators:

Regularly monitor and act upon leading indicators such as near-miss reports, unsafe behaviors, and deviations in process parameters. Early intervention based on these indicators can prevent major incidents. - Maintain Living PHA and MOC Systems:

Treat Process Hazard Analyses (PHAs) and Management of Change (MOC) documents as dynamic tools. Update them promptly when changes occur, and schedule regular reviews even in the absence of major modifications. - Enhance Contractor Management:

Develop robust contractor selection, onboarding, training, and oversight programs. Ensure contractors fully understand site-specific safety expectations and verify compliance regularly. - Digitize and Centralize Documentation:

Utilize digital platforms to manage PHAs, MOCs, mechanical integrity records, and training certifications. This improves traceability, audit readiness, and knowledge retention across organizational changes. - Integrate PSM with Other Management Systems:

Harmonize PSM elements with environmental, health, and other safety management systems (such as ISO 45001 or ISO 14001) to create a cohesive and efficient risk management structure. - Continuous Training and Competency Assurance:

Implement comprehensive training programs that include regular refresher courses, practical exercises, and competency assessments for both employees and contractors.

Future Trends

The future of Process Safety Management (PSM) is being shaped by rapid advancements in technology, shifting regulatory expectations, and evolving industrial practices. Key future trends include:

- Integration of Artificial Intelligence (AI) and Machine Learning (ML):

AI and ML technologies are increasingly used to predict equipment failures, optimize maintenance schedules, and identify hidden process risks before they escalate into incidents. - Digitalization and Industry 4.0:

The adoption of IoT (Internet of Things), cloud computing, and big data analytics enables real-time monitoring of critical process parameters, leading to faster decision-making and enhanced safety performance. - Predictive Risk Management:

Moving from reactive approaches to predictive models that forecast potential failures and near-misses, helping organizations take preventive actions proactively. - Advanced Training Methods:

Virtual reality (VR), augmented reality (AR), and simulation-based training are becoming common, providing employees with realistic, immersive experiences for better learning and hazard recognition. - Sustainability and Climate Change Considerations:

Future regulations may require companies to integrate environmental risks into PSM programs, especially as chemical processes face challenges linked to climate change, resource scarcity, and new energy sources. - Enhanced Regulatory Expectations:

Regulatory bodies are expected to push for more rigorous verification of PSM programs, with greater emphasis on independent audits and transparent public reporting.

Final Conclusion

The OSHA Process Safety Management (PSM) standard, codified in 29 CFR 1910.119, serves as a fundamental framework for managing highly hazardous chemicals in industries. It aims to prevent catastrophic incidents that could endanger workers, the public, and the environment.

Through the implementation of the 14 essential PSM elements — such as Process Hazard Analysis (PHA), Mechanical Integrity, and Management of Change (MOC) — organizations can systematically control risks and build a robust safety culture.

However, compliance should not be seen as a checkbox activity; rather, it must be deeply integrated into the operational philosophy of the company. The evolving landscape of technology, regulations, and industry best practices demands continuous improvement, adaptation, and innovation in PSM systems.

Looking ahead, the integration of AI, predictive analytics, and advanced training methods will reshape how organizations manage process safety. A proactive, forward-thinking approach to PSM will not only protect assets and human lives but also contribute to business continuity and environmental stewardship.

Ultimately, the true success of PSM lies in leadership commitment, employee engagement, and an unwavering dedication to operational excellence.

References

- Occupational Safety and Health Administration (OSHA) (1992). Process Safety Management of Highly Hazardous Chemicals (29 CFR 1910.119). Available at: https://www.osha.gov/laws regs/regulations/standardnumber/1910/1910.119

- U.S. Chemical Safety and Hazard Investigation Board (CSB) (Various Years). Investigation Reports. Available at: https://www.csb.gov/investigations/

- Center for Chemical Process Safety (CCPS) (2007). Guidelines for Risk Based Process Safety. American Institute of Chemical Engineers (AIChE).

- Personal experience of the author in the implementation of Process Safety Management (PSM) in various industries, particularly in the chemical and oil and gas sectors.